Water Cooling Channels Decrease 3D Printed Mold Tool's Cycle Time by 50% - Fortify

Fortify and PTC worked together to prove out if water cooling channels designed into the 3D printed mold tool could help reduce cycle time.

A review on the tooling technologies for composites manufacturing of aerospace structures: materials, structures and processes - ScienceDirect

How to Speed up Injection Molding Cooling and Cycle Time - Immould

Review on 3D printing techniques for cutting tools with cooling channels - ScienceDirect

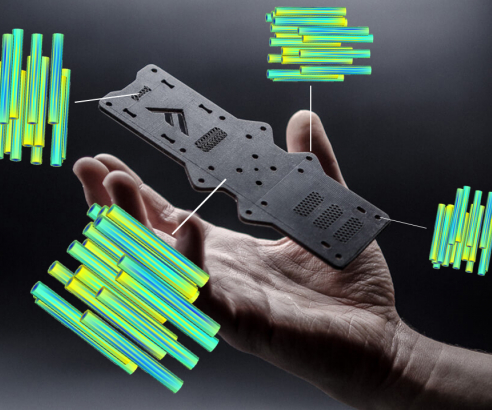

Magnetic 3D printing the next generation of tailored composites

Reshaping the Mold: How Metal 3D Printing Can Improve Tooling - Velo3D

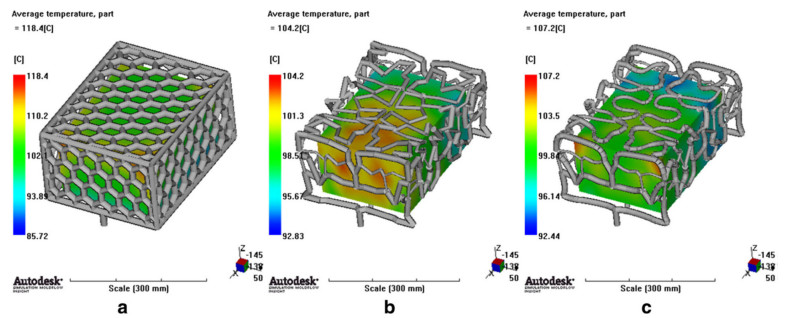

Review of conformal cooling system design and additive manufacturing for injection molds

Technology Roundup: Moldmaking Technologies You'll See in the 2021 Sourcing Guide

Metal 3D Printed Conformally-Cooled Injection Mold Increases Production Rate by 30% - Miller 3D

JEC Europe 2013 new product showcase

Digital Tooling Cooling Channels

Conformal cooling: How Additive Manufacturing benefits injection moulding

:strip_icc()/pic7389885.jpg)